Over time, I have been drawn to the “still-pond” look. Being able to view fish through an undisturbed surface is the main attraction. I’m partial to formal ponds, but this doesn’t mean a garden pond can’t have the same still-pond effect, with a few adjustments.

Part 2 of the Series | Drain and Filtration Design for a “Still-Pond” Look

The Ripple Effect

Waterfalls are beautiful and add much-needed oxygen to a pond, but they turbinate the surface. This is helpful when it comes to creating a healthy system, but the surface remains disturbed. When you’re trying to craft that glassy surface on a koi pond, the main issue is the demand for a high turnover rate. Using oxygenated filtration such as a moving bed, shower filter or dilution reactor, and returning the water through a small spill and current jets is a good option, but sometimes, depending on the shape, it can cause a lot of current in some areas. Because of these situations, I like to use airlift-powered circulation coupled with my vertical pond return bottom drains, or VPRs.

Water in a pond stratifies with the worst water quality at the bottom and the best at the top. Massively circulating the water from bottom to top with air is one of the key elements in lake or large, natural-pond management. Keeping aerators on continuously in a koi pond maintains a healthy environment, but it makes it hard to see the fish. VPRs bring water back into the pond through the center of the drain dome. This creates a toroidal-current effect and an air dome usually on the top of the drain cover, but it can be anywhere on the pond floor. As the water is directed upward toward the surface, it draws additional water from the surrounding floor. When this is part of a drain assembly, water is drawn toward the bottom drain with more effect. The VPR allows for a high volume of bottom-to-top circulation without disturbing the surface of the pond, provided the depth is adequate for the volume being returned.

Bigger Pond, Bigger House

I wrote an article in the May/June 2017 issue about a pond I helped repair and then expand on four separate occasions. This was unusual, because in the pond industry, return customers are usually limited to maintenance and repairs.

Once you have an idea of the total targeted flow rate, you must first determine how to get that volume out of the pond. The total exit volume will come from the four 4-inch bottom drains, two direct-suction skimmers and one 2-inch midwater drain.

As it happens, a couple of months after the article came out, Chad, the owner of that particular pond called me. “Kent, my pond isn’t big enough!” The original series of rebuilds had brought him into the neighborhood of 6,000 gallons, and he had been doing a great job of maintenance and koi husbandry.

I told him there was no practical way of making his pond larger. “I know,” he replied. “So I bought a new house.” The new house was just a couple of miles away in the same community.

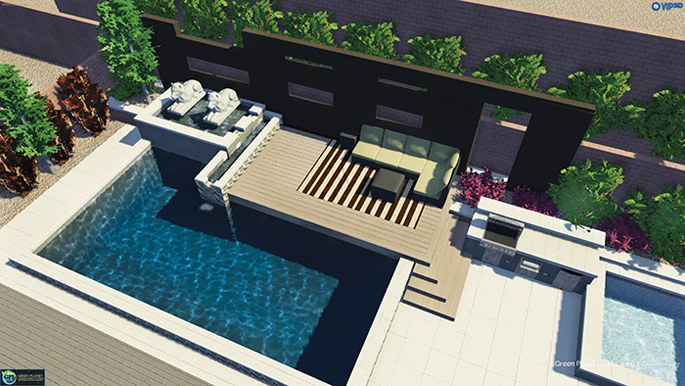

Over the next few months, we designed and constructed a new pond. He also did a complete makeover of the existing backyard and pool, bringing in Damon Lang of Green Planet Landscaping for the design and Duane Forte of Laguna Pools for the construction. Chad worked with Damon to come up with a beautiful plan that matched the pool with the pond finishes, making it look like they belonged together. Chad wanted to add a barbecue area between the pool and pond and a deck overlooking the pond. He also wanted a raised pool that would be the home for a pair of custom carved marble Foo dogs with a small trough pouring back into the pond, which would be the only “feature” in the design.

The Ultimate Drain Assembly

The goal was something a bit more than 15,000 gallons, and my job was to make it function. This would be a giant “still” pond, so my mind immediately went toward airlift-operated VPRs. In the past, I have modified existing drains, but it was very time consuming. With four drains on this pond, I decided to create a mold for my ultimate drain assembly, incorporating everything I had learned modifying other drains.

The body of the new drain has a 4-inch outlet coming out from the bottom edge at a 22.5-degree angle from the lowest point on the side to prevent debris entrapment on the bottom. This makes connecting the outlet pipe a smoother run, eliminating the need for a pair of 22.5, 45 or 90-degree fittings to get below a concrete shell. For liner application, you can insert a 22.5-degree street fitting and go horizontally out under the liner. For concrete, you can attach a length of 4-inch pipe as necessary and then use one standard 22.5-degree fitting to go horizontally under the shell. The return inlet is 3 inches for this pond, and both outlet and inlet fittings are threaded on the inside for pressure testing and keeping the pipes clean throughout construction. The upper edge of the body has a recessed, clamping-flange edge, making the clamp ring sit flush with the surface to prevent buildup of debris around the edge under the dome.

Because this was to be a raised-edge formal pond, it made the use of side-mounted skimmers difficult, because they would bulge out beyond the beam of the pond. Sometimes you can find a corner near a back edge where the bulge can be incorporated into the landscape or another structural element, but that wasn’t the case in this design. For this layout, I used two of my Aqua-niche skimmers mounted on two corner steps inside the front wall of the pond. These disappear in the design and look and function like holes in the surface of the water. The upper edge of the skimmer body has a flanged clamping edge for the sealing surface to attach to. In this case, the sealing surface was polyurea, but they can be used in liner applications, also. The clamping flange is recessed to keep the clamp ring flush with the surface.

Total Targeted Flow Rate

In any pond design, it’s important to calculate the total water flow through filtration based on pond volume. The target was something over 15,000 gallons, so a targeted total water volume through filtration at a 1 ½ times-per-hour turnover rate should be in the range of 22,000 gallons per hour. The turnover rate isn’t an absolute, but a general target is based on the overall filtration type, circulation patterns, dissolved oxygen content, climate, fish load, etc. The better you understand and meet each of the criteria, the less critical the absolute number becomes.

Once you have an idea of the total targeted flow rate, you must first determine how to get that volume out of the pond. The total exit volume will come from the four 4-inch bottom drains, two direct-suction skimmers and one 2-inch midwater drain. The bottom drains flow into one of my 500-gallon radial separator prefilters and then into two air-driven dilution reactors with a 6-inch airlift in the center of each one. At a gravity flow rate of 3,600 to 4,000 gallons per hour through a 4-inch line, the four bottom drains should yield 16,000 gallons per hour, which is the approximate total volume of the pond. The skimmer-midwater circuit will make up the rest. Each of the 6-inch airlifts can flow at a rate of approximately 10,000 gallons per hour if plumbed correctly as gravity flow systems. The four outlets from the radial separator consist of 4-inch lines supporting four of my 8-inch circular weirs. Two circular weirs feed each of the biofilters, so each airlift is fed by two 4-inch lines. This circuit should yield between 16,000 and 20,000 gallons per hour when running.

Prime Real Estate

The design has a raised pool supporting the Foo dogs. This upper pool cannot be run on airlifts, so a standard pond pump was used. This affords the opportunity to use an upflow sand and gravel filter as the fines filter and stabilizing platform for the pond’s bacterial colonies. This is my favorite fines filter, because it creates the best water clarity of any filter I have ever used. The natural rock — the sand and gravel — is the type of real estate that bacteria find the most attractive.

The two skimmers and midwater drains are each connected at the intake of a WLim Wave I ¼-Horsepower pump with a valve on each for balance and flow control. The pump delivers the water into a WLim EZR upflow sand and gravel filter, which is about 400 gallons. The top of the tank is approximately 6 inches above the water line in the upper pool and is gravity-fed through a 4-inch line from the tank to the floor inlets at the back of the pool. Water fills the pool and exits through two 12-inch spills into the side of the trough and three adjustable floor returns that act as current jets at the bottom of the pond below the pool. This would provide another 6,000 gallons per hour of total flow, which should help us reach the target.

The airlifts return water through the four bottom drains as 3-inch lines and 1.5-inch return jets. The water exits the airlifts and enters a 6-inch air purge chamber. The purge chamber allows the bubbles to be removed as the water travels downward, preventing bubble buildup, restriction and burping in the return piping.

At the base of each purge tank, the water is divided into two 3-inch lines for two of the bottom drain returns and three 1.5-inch side wall returns. This is a little less than the total diameter of a 6-inch pipe, but the restriction will be made up for with a slightly higher water level, or head, in the airlift, which will create a faster flow rate through the pipes back to the pond.

The air-driven dilution reactors are like a moving bed without the moving media. A moving bed creates multiple opportunities for the bacteria on the media to come in contact with the ammonia in the water through tumbling the media with air. For each one-time pass-through of pumped water volume, the water acts like it’s going through multiple filters.

In an air-driven dilution reactor, the media is stationary, and the water is cycled through the inner and outer chambers multiple times for each one-time pass-through of pumped water volume with no moving media. I prefer Bacti-twist, but many different media can be used.

The plumbers for Laguna Pools did a great job, even though they had never before seen a design using all gravity-flow in this manner. In the next issue, we’ll put the pond together.

I prefer slope bottom drain to the center of the pond if you want a better gravity to your equipment