A pond vacuum is a valuable, universal tool found in the toolbox of most pond contractors, landscapers, maintenance personnel and other industry professionals.

OASE, a global manufacturer in the fountain and water gardening industry, debuted the first pond vacuum on the market, the PondoVac, about 15 years ago. The company has since released three updates and sold hundreds of thousands of units on an annual basis.

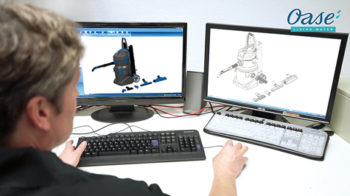

OASE recently announced its plan to launch the next version of its signature product, the PondoVac 5.

You might ask yourself, “Why do companies keep releasing new versions of the same product?” The answer is simple: product development serves as the foundation of a manufacturer’s business. Continuous changes in market demand, business trends and the needs of the customer drive companies to continuously develop and improve its products.

When OASE launches the PondoVac 5 in North America this May, it will serve as the culmination of two long years of research and development that involved multiple departments and large teams of employees around the world. Its new features are direct responses to customer feedback. The newest version of PondoVac may look like just another pond vacuum, but it is optimized for commercial use with sturdier wheels, professional accessories and an integrated discharge pump that allows the user to continuously discharge the waste, even uphill.

So how do the brains behind these operations decide what products to develop or upgrade and then bring them to market? The process is a little more complex than it might appear on the surface — and not everybody does it the same way.

The Development Gauntlet

Off-the-shelf products can be divided into three groups: brand-new products, improvements to existing products and competitive alternatives to other companies’ products. While a new invention carries its own degree of enthusiasm and anticipation, most new products on the shelf fall into the latter two categories.

OASE’s director of sales, Frayne McAtee, said that the company pays attention to market trends to determine what might be missing from the market or how existing products might be better utilized.

“The excitement is always in the next generation of products,” McAtee said. “What are we doing to evolve in the industry?”

After all, every product has its own life cycle. As each nears its retirement, consumers start to turn to the marketplace to find the latest and greatest replacements.

“As time goes on, products tend to improve,” said Andy Schoenberger, product manager of Little Giant Pump Company, a division of Franklin Electric. “We want to offer the best in the marketplace that also simplifies the work for the contractor.”

Brandon Dwyer, the vice president of product management for Atlantic Water Gardens, echoed his industry colleagues. “New products are the lifeblood of all manufacturers, but redesigns and upgrades can be just as important,” Dwyer said. “Sometimes a little tweak or an added feature can make a big difference.”

Some companies like OASE have up to eight distinct product categories, each with its own team and manager who stay involved in every stage of the global product development process. Other companies like EasyPro Pond Products might involve five to eight of its employees in its development process, from engineering and packaging to purchasing and marketing.

“Ever since we started, it’s been this way,” said Dave Ouwinga, the owner of EasyPro, which was founded by his parents as Stony Creek Fisheries in 1970.

“Milestone Zero”

Regardless of how robust the system or how full the roster, most companies place a high emphasis on what McAtee calls “Milestone Zero,” or the initial assessment of product viability. The milestone process used by OASE often involves multiple presentations that include all departments. If executives cannot be sold on a business case that is backed by solid market research and other research and development efforts, a product will not advance past this initial stage.

If a product isn’t already on the market, that doesn’t necessarily indicate an automatic green light. Ouwinga, for example, has been awarded more than five patents for new concepts by the United States Patent Office — but not all have been developed into products.

“For me, I have to say, can I do it and make money — and make money feasibly?” he said. “We have to make sure that we have something the market wants, and that it will sell,” Schoenberger added.

“Is the product durable, serviceable, easily installed and maintained?” Dwyer said. “If the answer to any of these questions is no, then it’s back to the drawing board.”

Scott Rhodes, the vice president of marketing at Aquascape, a leading manufacturer of water features, said that his company also places an emphasis on product line extension possibilities. “We have a complete lighting line, for example,” he said. “But we find that there could always be tweaks and changes to improve it.”

Research & Development

If a product is deemed initially feasible, the often expensive research and development process begins. Depending on the nature of the product and company, this can take a matter of months or up to several years.

Rhodes and his colleague, Aquascape product manager Dave Kelly, took on the R&D efforts associated with the Automatic Dosing System that was released a couple of years ago. Using an IV system procured from a hospital, they experimented with dosing a pond with water treatments in a similar way to how medical professionals dose an ill patient with antibiotics, he said. The development process took many months, but it resulted in an effective product that was the first of its kind in the market.

“R&D is the center of Aquascape,” Rhodes said. “Our main advantage is that we have a full-time installation crew. By putting ponds in the ground every single day, we are able to figure out where the market’s needs are.”

Atlantic Water Gardens has developed a range of strategies for mitigating the typically long R&D phase. “Advancements in rapid prototyping allow us to test multiple versions of a design early in the process,” Dwyer said. “This enables us to evaluate our concepts and refine a product design long before we make the commitment to produce it.”

“We’ve had some products with the item already made, and all we have to do is modify a mold,” Ouwinga of EasyPro added. “After three weeks and a minimal investment, we can start selling and capitalizing right away. But if it needs six months to a year of research and development, it could take years for us to see a payback.

A Team Effort

Frequent meetings between the product teams and other departments are essential at this point to ensure everyone is on the same page when the product goes into mass production.

“You have to get the entire company involved in the process,” McAtee said. The product teams at OASE bring marketing and sales into the loop and train customer service, all while ensuring that the operations and logistics side of the business is ready to meet demand.

Extensive field testing is typically required to validate the capabilities of any new product. Safety and product certification is also a key step in advance of releasing the product to market. “We take pride in knowing our products are third-party certified,” Schoenberger said. “We have to design a product for both functionality and safety.”

An Accidental Manufacturer

Not all inventors are cut from the same mold or are employed by the industry’s large companies. Eric Triplett, known in the industry as The Pond Digger, invented the Helix Life Support Pond Filtration system in response to his own needs as a pond builder. He calls himself an “accidental manufacturer.”

“My intention was not really even to bring it to market,” he said. “I don’t build with a manufacturer’s philosophy. This is what I wanted for my team and what we build, and now people want it.”

In response to market demand, Triplett has found himself not only building ponds, but also manufacturing a variety of skimmer and filtration systems under his Helix product line. Based in Southern California, he and his team handle a variety of hand-fabrication and quality-control duties at their own facility. Triplett’s focus is still integrating his products into his own pond-building business, but orders for his products continue to come in from around the country.

“Sometimes they’re ordering more quickly than I can make them,” he said. “But when someone orders a product, I touch that piece. I don’t have huge trucks and supply chains. But I like that. I’d rather be making them on demand. It gives it a more personal touch.”

Ready to Launch

Whether small, large or “accidental,” every inventor dreams of launch day. However, some of the most important steps in product development occur concurrently with the launch, or immediately thereafter.

“You have to make sure you have a great training program with videos and website content,” Schoenberger said. “It needs to be known in the marketplace and seen across different publications.”

At the end of the day, manufacturers universally agree that it is essential for companies to stay in tune with the voice of the customer. Little Giant has a growing focus on energy efficiency and solar power, which are two trending, hot-button issues across the spectrum of manufacturing.

“The efforts put into developing energy-efficient LED light bulbs has carried over into our motor division,” Schoenberger said. “Energy efficiency has become a focus in almost all of our products.”

Little Giant has also adopted a systems-oriented approach in its manufacturing, looking to provide the customer with a “total package” of components for a particular product all at one time, reducing the need for customers and contractors to seek out auxiliary parts.

“Diversification is the key,” added Ouwinga of EasyPro. “Years ago, it was ponds and pond kits. Now, the industry has evolved. If you’ve got your blinders on, you’re hurting. If you’re not diversifying, you’re shrinking. But if you’re coming up with new, fresh ideas, you get people excited about it.” McAtee cited OASE’s emphasis on adjusting with the market to stay relevant.

McAtee cited OASE’s emphasis on adjusting with the market to stay relevant. “We are trying to push our water garden category forward,” McAtee said. “If we can get consumers excited, it helps everyone. We all want to be a part of a vital and dynamic industry.”

“Expanding our industry reach is important,” added Dwyer of Atlantic Water Gardens. “We’ve put a lot of effort into developing a system of products and information that make it easier for contractors to add water to their hardscape designs.”

Aquascape’s Rhodes seconded his industry colleagues and placed a further importance on the company’s active role in inducing demand.

“Our whole goal is to create consumer demand,” he said. “So we’re not so worried about whether we’re going to sell products in the market. What’s more important to us as a company is introducing water features to new generations. As an industry, we need to come together and get along to create demand for this business.”

To Be or Not to Be?

Creating a bigger industry naturally means bringing in more people with more ideas and — inevitably — more products in the marketplace.

Whether it’s a state-of-the-art pond vacuum, an innovative dosing system or another invention no one has previously thought of, perhaps you’ve come up with a groundbreaking idea. So, when do the profits start rolling in?

Not so fast. Regardless of how many ripples your new idea might send throughout the pond world, it’s always important to take it a step further. Can your idea survive the development gauntlet to become a finished product? That is the question.