Many builders and contractors have a difficult time with drawing or sketching a layout for a living water feature design. Landscape architects leave it at drawing a shape on the plans, with no allowance for filtration or proper circulation in the basic shape, creating a “design build” situation. This usually leads to a set of plans with no accommodation for the volume of filtration required by the project.

Over the last decade or so my business has moved to manufacturing and assisting homeowners, builders, contractors and architects in properly laying out the feature and the life-support systems that go along with it. There are several ways to build a pond, both structurally and functionally, with many decisions based on location, use, expectations and aesthetics. There are multiple concepts and components surrounding prefiltration, biofiltration and circulation that all work individually but don’t necessarily work well together on a given project. Choosing the best combination of products to accomplish the goal is the challenge.

Manufacturers in other industries have component “cut sheets” that give the designer or builder the size, shape and specifications of individual parts and products they manufacture. The pond industry is severely lacking in this regard.

3D SketchUps

Several years ago I started creating two-dimensional “cut sheets” for several components — both mine and other manufacturers — and over the last few years I’ve started using the 3D drawing program SketchUp. It’s a free download, and once you get used to using it you can upgrade to the professional version. It can be incorporated into CAD drawings and a backyard can be downloaded from Google Earth, allowing anyone to import a design directly into the space in proportion.

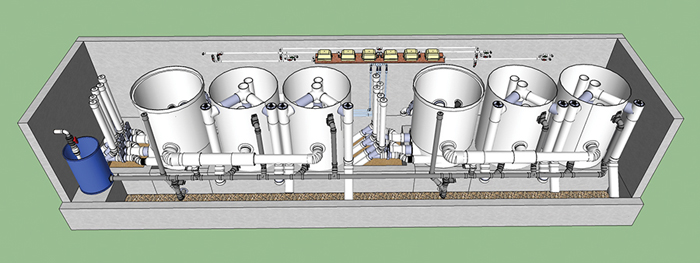

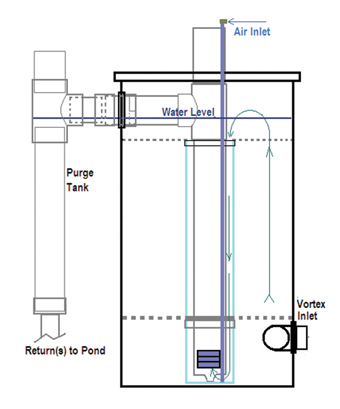

With cut sheets I can help architects, designers or contractors get an idea of what they will be dealing with and help them allow for the space required. This is very helpful, considering many of these individuals have never been involved in “proper” pond construction and have no idea what’s involved or even what the components look like. Cut sheets, along with construction photos of installations, can be very helpful in assisting with the bidding and construction estimate challenges.Beyond the 2D images is 3D. This is much more work but it’s a great deal of fun. A 3D SketchUp drawing can really bring the project to life. A landscape architect or designer can get a much better grasp of the system and space required. With SketchUp a component library is available as a direct download for many items from manufacturers and designers. Sadly, there isn’t much available for the live water feature industry and I’ve had to make my own component library for most of the products I use. You can download small PVC fittings and components, but for larger pipe sizes you won’t find much there. I started making my own components primarily because my air-lift systems use three-, four-, six- and eight-inch pipe and fittings. Nowadays I make new components when I need them for a specific layout and add them to my library.

Formal designs with remote filter pits can benefit greatly from a 3D image, especially when building from scratch. Knowing the size and shape of an existing filter room allows you to place components in and move them around for the best fit. I use the 3D mostly for component layout, but occasionally I draw an entire pond. Pulling natural-looking stones from the surface is more difficult than making components, but it can be done.

Many of my projects have been long-distance where I’m just supplying the equipment. Sending a 3D image of the equipment layout and location is very helpful, and if the person on the receiving end doesn’t have SketchUp I can rotate the image to the view I want and print or e-mail it as a 2D image, as shown in this article.

I used 3D imaging on my SPCA project in New Orleans last year and, considering none of the contractors involved had ever built a pond before, it gave me a level of control I wouldn’t have had otherwise. This project had three formal raised ponds, all with identical filtration run on air.

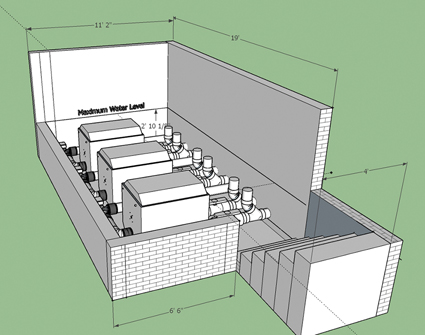

I also had a chance to create a filtration system for a hospital project from the same landscape architect and, although it didn’t go through, the 3D imaging showed everyone involved what would be needed for a 40,000-gallon, formal pond run on air.

Currently I’m working on a rebuild project in Hawaii. It’s a difficult layout with a new remote building for the prefiltration. None of this has been constructed yet, and the ProfiDrum prefilters and the axial flow pumps are coming from the Netherlands. In the meantime, a 3D image of the minimum space required was created for the architect and contractors. The manufacturer doesn’t have much more than a photograph of the new pump and a general dimensional drawing of the prefilter, so I had to create them. This allows everyone involved to move forward and make decisions.

The ability to be able to send someone a cut sheet or 2D version of a filtration unit can be very helpful and move your company to a new level of assistance for your customers. If you would like some help with pond components, please contact me. I may not have exactly what you’re looking for but, depending on schedule, I might be able to come up with something for you.