Publisher’s Note: A previous version of this article was originally published in January 2020 . Kent Wallace has updated the original piece with additional information and photos. Enjoy this “updated flashback!”

After over 20 years in this industry, I have found that many products manufactured for pond construction are just new versions of components and methods that have been around for years. This begs the question, when did it all start? Who were the creators of our industry’s components?

Most of us have no idea about the origins of the products in our chosen profession. I came from the koi world and had little knowledge of the water garden industry. I started my research by reading through the only information I had at the time — a stack of my father’s KOI USA magazines. I pored through them, talked to every vendor who would speak with me. I picked their brain about how to build a koi pond for my first client. All I knew at the time was that my dad’s pond was a lot of work.

My Mentors

I was mentored early on by William Lim of the W. Lim Corporation. Later, I was officially introduced to water gardening by “The Pond Digger” Eric Triplett, who attended a talk I was giving to a koi club in late 2005. Up to that point, I had been heavily involved in some internet forums within the koi world. I learned how to modify existing components to make them better adapted for koi ponds.

But where did all the stuff we were modifying come from? We must keep in mind that a product is rarely a standalone creation. We need to separate the idea (or method) from the product.

Filtration

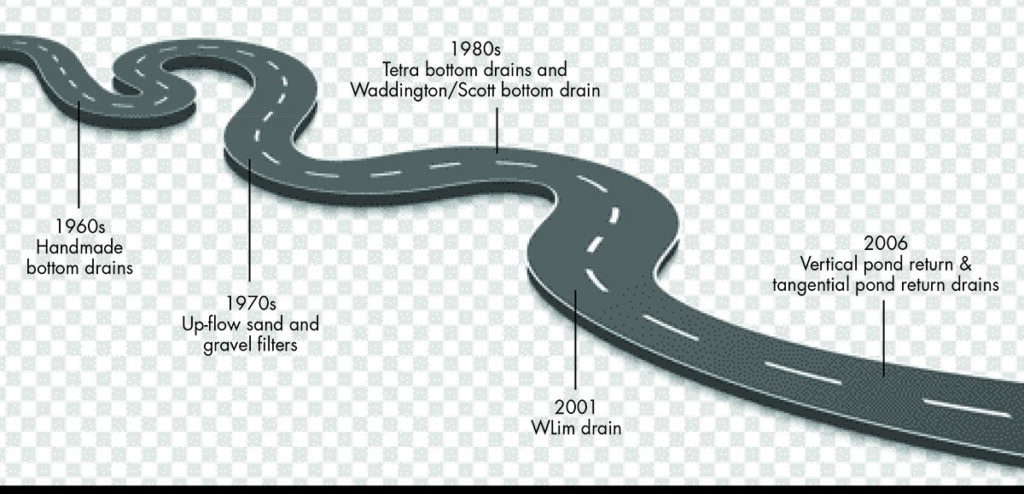

The idea of bottom drains as a product came from the method of running a pond by gravity flow, which was developed in the late ‘50s and early ‘60s in Japan. This principle had long been used in Japan, but mostly from midwater feeds, from a side feed off the bottom, and finally a from a bottom pipe covered with a metal plate.

In the ‘60s, Seije Kaneshiro (E&S) and Mitch Nakamaru (Asahi Koi) started importing koi into the United States through California. They hand-built systems with bottom-drain piping leading to a settlement chamber, and then to square or rectangular tanks filled with rock, gravel and sometimes lava rock. This version was very much a Japanese style of flow through filtration. The bottom drains consisted of a pipe coming through the floor covered by a concrete dome with small feet to support it above the surface.

During that same time period, another gentleman named Joe Zdeb was handmaking his own version of a bottom drain. However, he didn’t sell them as a product; he just made them for his own projects. He modified the rock and gravel filter to an up-flow design of layered, rounded rock with a sand layer on top. This filter’s best feature is the air blower, which cleans in a “forward wash,” or in the same direction that it flows. The first of these filters was installed in San Francisco’s Steinhart Aquarium around 1970. Zdeb was a well-known koi hobbyist and, along with Burt Ballou and others, promoted and built these filters for other koi hobbyists.

Weddington and Scott’s Contributions

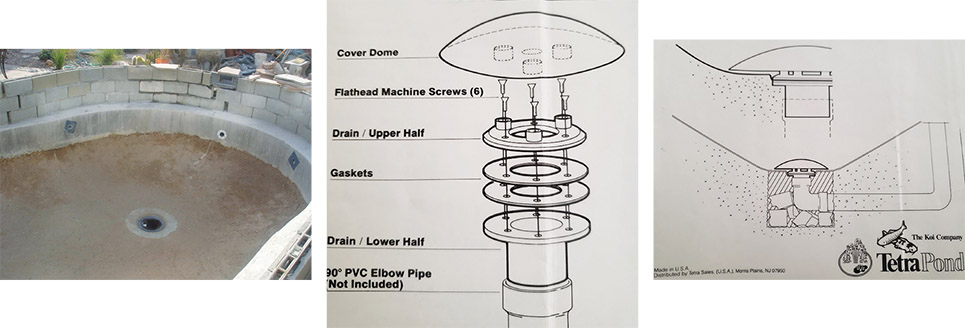

In 1980, Peter Waddington and Howard Scott, two koi hobbyists in England, designed the first bottom drain with a sump area integrated into it as a product. They didn’t invent the method, but they created a product that followed the method already in use to make the construction simpler. A few years later, Bob Spindola, a koi hobbyist in the United States, was speaking to groups of water garden enthusiasts and conveying the importance of pulling water from the bottom of a pond — not just the surface.

The water gardeners in attendance weren’t thrilled with the idea of digging up their ponds to install a bottom-drain system. Working as a consultant with Tetra, whose market was water gardens, Spindola designed the first retrofit bottom drain that sat on the pond floor with a pipe running up and over the side to a pump. Spindola also designed the first Tetra pond bottom drain to be installed under the liner, which is still sold today. His wife Pam found some original drawings of these and offered them to me for this article.

William Lim’s Molded Bottom Drain

Since that time, bottom drains have evolved into 4-inch and 6-inch outlet versions with or without aeration. In 2001 William Lim introduced his molded bottom drain with a great shape. The bottom was curved like the inside of a Meerschaum pipe so no debris could be trapped in a sump area.

A big advance came in 2001 when Lim started commercially manufacturing this filter with the molded tank. It had a step in the lower edge to support the perimeter of the divider plater and the enormous weight of the rock, gravel and sand media without it making it rest on the distribution ray assembly. At approximately 300 gallons of water plus media, the EZR, as it is called, weighs around 4,800 pounds when full and requires a good-sized concrete slab to support the weight. It is also custom made for projects constructed by The Pond Company in California as the Z-Biofilter. I (among others) make 55-gallon-drum kits, allowing these to be built on-site in a smaller version. The up-flow sand and gravel filter is one of the earliest filters and still one of my favorites.

Aeration

I’m not sure who decided to put the first air domes on the top of the drain cover, but hobbyists were already using air sticks and air diffusers from the wastewater treatment industry in the ‘80s. This was a way to both aerate the water column and move water from the bottom to the top surface. This concept came about after the 1977 Clean Water Act, where aeration was one of the solutions used to prevent water stratification and stagnation in large ponds and small lakes.

Bottom-drain dome aeration wasn’t as much an invention as it was a refinement that followed an existing method. Placing the air disc above the drain dome creates a toroidal effect, lifting the water above the drain and sending it across the surface of the pond. As it reaches the outer edges, it travels downward and across the bottom toward the drain, creating a toroidal pattern of complete circulation in the pond.

In late 2006, a group of us industry types were having conversations about aeration and returning water vertically upward through the bottom of the pond instead of just through the sides. Michael Anderson and I were tossing around the idea of returning water upward through the center of a bottom drain, creating the toroidal circulation effect with water instead of air. I decided to integrate one on a pond build in spring 2007. It worked great, and over the next few years, I modified a couple of other manufacturers’ bottom drains to do the same. I was molding my own by 2017. I didn’t invent the vertical pond return drain as much as I followed existing methods with a product.

Returns Through Liner

In the late ‘90s when I first started building ponds, pond returns through the liner were made of basically two types. The first was called a pipe boot, where you would cut a hole in the liner smaller than the pipe you were pushing through it. When the pipe was inserted, the liner would stretch and form a small shoulder of rubber that could be clamped to seal it.

The second method was to use a tank bulkhead to sandwich the liner between the nut and body. The clamp area was small so that plastic washers could be used on either side of the liner to spread out the clamping area. This was all sealed in place with silicone or polyurethane sealant. Terms like TPR (tangential pond return) for angled returns were used to describe an angled directional return. VPR (vertical pond returns) came up from the bottom of the pond, while GPR (ground pond returns) sent water through the gap between a pair of bottom drains.

In 2005, the concept of a 2-inch PVC pipe cut at a 45-degree angle and plastic welded onto the back of a piece of PVC plate as a TPR was conceived in England. Shortly thereafter, Dream Pond started molding straight and 45-degree fittings in 1 ½-inch and 2-inch sizes for use in the pond industry, along with their own version of a bottom drain. I now make these in every size from ½ to 8 inches. These were all products developed from methods already in use in our budding industry. Dream Pond’s second drain adopted the curved internal shape of the W. Lim drain, as did mine later.

Other Pond Products

What we know now as vortex settlement tanks were originally a large rectangular chamber that slowed down the speed of the water enough to allow the settlement of any solids heavier than water. This process took up a lot of space, and round tanks circulating in a vortex pattern were shown to have more dwell time in a smaller space. At some point in the late ‘70s or early ‘80s, cone-bottom hopper tanks manufactured by companies like Polytank were adapted. The cone-shaped bottom collected the debris in a smaller area in the tank’s center, making discharge and cleaning easier.

In my own designs, I originally used the Tetra bottom drain as a midwater drain, and later the original Dream Pond drain. I mounted them vertically on the pond wall for several years until Dream Pond made a separate, screened cover to be used as a dedicated midwater drain. I have also made my version of a midwater drain using an approved grated swimming pool drain cover to comply with pool-industry codes. These are products based on the original method of removing water from a pond.

Early skimmers for ponds were pool skimmers modified for our use. A large basket with a lot of capacity wasn’t available at the time. The bottoms were regularly cut off and adapted for 3-inch and 4-inch outlets, allowing gravity flow.

My Evolution in Drains

My evolution through the bottom drains I manufacture started with quarantine tanks and small ponds. There wasn’t much out there for these systems, so I started making a small drain for these with a 3-inch tee. I could trim down the tee and get a very low profile since quarantine tanks are regularly set on blocks for some ground clearance. The tee gives an immediate 90-degree turn sideways, and the opposite end can be used for an airline inlet.

The air line comes in and turns upward through the center, and a 5-inch air disc can be used to hold down the legged dome. The connection to the tank is with a 3-inch shower drain trimmed to fit inside the 3-inch tee. The nice thing about this drain is that it has a very low profile.

After that, I started converting the Tetra and original Dream Pond drains into mid-water drains. Once I started using the 8-inch grated swimming pool drain covers to pass pool codes, I realized that these could also be used as a bottom drain for rock-bottom ponds because the grating keeps the rocks out.

Next came my 3-inch and 4-inch aerated bottom drains that evolved from my modifications to the original Dream Pond drain that incorporated air using a DWV heel 90-degree bend. The heel connection is used to mount the airline inlet with the addition of my own molded flange, including a recess for the clamp flange. The new dome has a 5-inch recessed air disc, eliminating the disc as a protrusion above the dome. I also have threaded versions of these to allow for pressure testing during construction or for passing pool codes.

I wanted to deal with the angle of the inlet on 4-inch bottom drains with an angled outlet. This eliminates a fitting and smooths the flow out of the drain and under concrete. The Ultimate Drain has a threaded 22-degree downward outlet and comes with a 22-degree street or flange fitting to get you out efficiently, depending on the depth necessary to go horizontal. The clamp flange is recessed, and the 9-inch air disc is recessed into the drain dome for a flush top.

This mold also incorporates the ability to create the vertical pond return. This has become my favorite method of pond circulation, whether it be gravity-flow return or pumped. My early versions were with a modified air diffuser disc, but those were very difficult to make. The final design uses air diffuser tubing which surrounds the vertical return with a tubular column of air.

My latest Drain

My latest drain is the 6-inch aerated drain. It too is threaded for pressure testing and has the recessed air disc in the drain dome. This drain is made along the lines of my original drains with a DWV Tee as the body, and I have a 6-inch tank connector to complement it. I can also make this in an 8-inch version. All these drains are built on the successes and issues of those who came before me. I’ve learned something from every conversation and every product I deal with. I’m always excited to see what others create to solve the issues they deal with in our industry as time moves forward.

Special thanks to Burt Ballou, Pam Spindola, Mat McCann, Tim Waddington, Eric Triplett and others for their insights into this little history.