One day at work I received a message on Snapchat message from a do-it-yourselfer about an hour away. He was looking for a plant source for a new pond he was building. About a week later, he texted me a design of the pond, which used advanced undergravel filtration by Helix — the Pond Digger design.

“Great!” I said. “Good luck. That’s quite the undertaking.” I told him that if he had any questions, I was just a phone call away.

A week or so later, he asked me if I would come and check it out. He was looking for ideas about what could be changed, and he wanted to make sure certain things were being done correctly.

I was impressed! The pond ended up being massive (for one DIYer) at 35-by-30 and 7 feet deep. The hole was dug; the pond was lined; and the back wall was almost completely rocked in. I voiced a few suggestions and some general advice on what steps he should take from that point forward.

Afterward, he asked if I could help him finish, as he felt a bit overwhelmed and wasn’t going to come close to meeting his deadline. I will say, this is usually a no-no when it comes to a contractor-client relationship, but seeing that he had proven himself already, I didn’t mind helping someone who seemed so passionate about doing it right the first time. After all, he had gotten pretty far by himself.

After talking a bit more, I asked him, “What made you want to do this? Not many people would tackle this kind of thing on their own.”

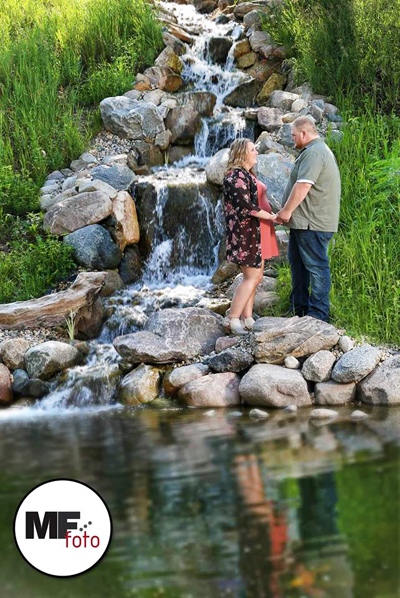

“I’ve always wanted a big pond with koi,” he replied. “My wife is a photographer and we are going use it and the waterfall for props. The Pond Digger made it look easy on YouTube!”

I knew from that point forward, we had to make a few changes. He went on to say that he wanted Niagara Falls in his backyard, and I just knew the original pumps and setup were not going to leave him happy with the end result. The slope was more than 25 feet of head, and that’s a lot of head if you are going for Niagara!

We ended up keeping one Sequence 8200 pump for the skimmers that went about halfway up the hill into the Biomech to reduce some of the head pressure. The other pump was an Artesian Pro AP 2-HF High Flow Waterfall Pump. At 15,000 gph, this pump was the heart of the pond. It would pull from the entire grid of the pond, which was on two different levels and in four separate sections, covering as much surface area as possible.

The grid is all 2 inches, which goes into a 4-inch manifold and then feeds a 12-by-12 wetlands filter with a 4-inch inlet at the top, just over the crest of the hill. With this setup, you cannot see it, and the waterfall looks like it comes naturally over the hill. The wetlands have a false bottom, with Ecoblocks and a 4-inch cleanout for easy backwashing.

The two of us ended up doing the whole thing in about two weeks. Week one was spent finishing the bottom of the pond. As there were two pairs of hands on the project, we could mix in some bigger support boulders for the walls. Next were the skimmers and main plumbing lines. Over the weekend, he completed the grid and got the rock on top of it. Week two was building the waterfall and the wetlands. The waterfall wasn’t too big of a challenge; it was just a bit tricky strapping and setting rock on steep slopes like that.

It was a fun challenge. It’s not every day you get to work hand in hand with a client like that, so that added a neat experience to whole project. A year later, it’s being used as a breathtaking backdrop for pictures of newlyweds and high school seniors!