A few months ago, I received a call from a couple relocating from California to Las Vegas. They had just purchased a new home and needed to move and quarantine their fish while a pond was built. Not only did they need help moving their fish and temporarily housing them, but they also needed assistance in designing a raised, formal pond. Of course, I agreed and supplied them with a tank and aeration. The quarantine tank was set up in the front courtyard.

Related Content | Drain & Filtration Design for a ‘Still-Pond’ Look

Structural Design

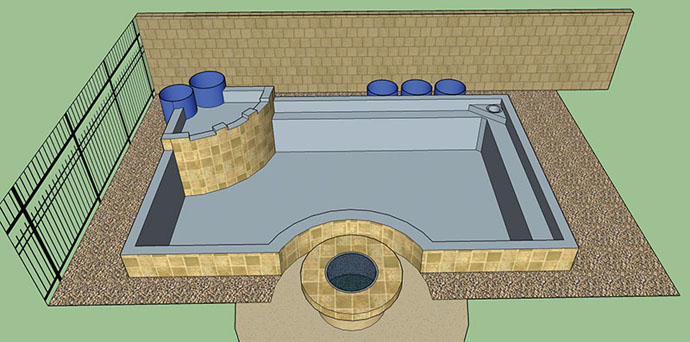

Brenda and Daryl’s backyard faced south, with open fencing on a golf course. A swimming pool and fire pit took up most of the backyard. A rectangular area of grass on the west end wrapped around the fire pit deck, giving the backyard a formal feel. I suggested a raised pond that would be the same shape and size as the grass area, which would allow pond-edge seating around the fire pit. A 3-foot line of hedges was along the fence, blocking the grass area from the golf course. The top of the water feature needed to be below the top of the hedge so it would not be seen from the golf course. I designed a set of low spills that dropped just a few inches and arched out from the biofilters and upper pool.

The precalculated volume was somewhere between 4,000 and 5,000 gallons, so a total turnover of at least 6,000 gph was necessary. With low spills and no splashing waterfalls for aeration, I chose to split the system between standard pumping and airlift pumping. Space between the west block wall and the pond edge was tight, but I could fit a series of 55-gallon drums down the side and still have room to walk. Two 3-inch aerated bottom drains would each flow into a pair of 55-gallon drum radial separators tied together for cleaning. The pair of prefilters incorporated a 3-inch connector pipe and knife valve for isolation, allowing for only one discharge pump instead of two for cleaning both tanks. Both tanks could be cleaned with one pump by opening the valve between the tanks.

Filtration Design

Each of the radial separators is connected to an air-driven dilution reactor (ADDR) through separate, 3-inch lines. The flow through the prefilters and aerated biofilter is created with a 4-inch airlift inside the ADDR. The airlift dumps into a 4-inch air-purge down-tube that splits up the water among four 2-inch returns about a foot off the floor in various locations. No valves are necessary on this system — just stand pipes inside the radial separator tanks for the inlets from the bottom drains, which are used during cleaning. The down-flow air-purge tube removes the bubbles from the water column, preventing burping and surging at the returns. This circuit will create approximately 4,000 gph of aerated flow, creating a fully oxygenated system. A drain line is located at the bottom of the ADDR to facilitate cleaning. This 2-inch line connects to the first prefilter tank and allows the same discharge pump in the prefilter to be used for cleaning this filter.

The upper pool and spills are operated with a Wlim Wave I 1/6 Horsepower pump at approximately 4,000 gph. The water is pulled from a corner, shelf-mounted, in-pond Aqua-niche skimmer and a midwater drain flowing to two upflow sand and gravel filters. The in-pond skimmer eliminates the bulge from the side of a raised-edge pond and keeps a cleaner top-cap look with no lid necessary.

Pond Construction

Hector Mardueno of Stonewall Creek Landscaping was contracted to build the pond. As a raised-edge pond, the sides become an architectural element. Hector and the owners chose to stucco the sides to match the home and found a top cap that complemented the colors of the pool tile and fire pit. The object was to create a raised pond that looked like it was part of the original backyard design.

This pond is designed with a concrete collar and shelf with solid-filled block walls and a dirt floor. Because of its shape, with its two convex curves protruding into the rectangle of the pond, the EPDM liner was going to have some serious wrinkles. Hector decided to cut and seam all the sides and corners to eliminate the wrinkles. This would be difficult, but he and his crew did an amazing job. The surfaces were parged with a cement-mortar mix to eliminate any lines that would show up in the liner, and the drains were concreted in place. The returns were held in place with cement to prevent movement over time.

Two radial separator prefilters and the ADDR biofilter were set in a row behind the west pond wall. The in-pond skimmer was concreted into the shelf on the northwest corner. The balance of the plumbing was finished and sanded in, and the underlayment was put in place. The liner was stretched in place with just a couple of inches of water on it to help hold it and allow for pulling and smoothing the wrinkles from the floor. Hector’s crew carefully trimmed the underlayment and darted the liner in the corners, and then seamed the lines. The curve around the fire pit was created as a sheet of liner that wrapped around the inside and was seamed a few inches above the floor along the curve.

The other difficult curve was below the waterfall pool and spills. The issue for the curve under the spills was the tile. The tile needed something to attach to, so Hector bent a thin piece of cement board around the curve just above the concrete collar and clamped it in the corners. He drilled several holes through the cement board and then filled the gap between the liner and cement board with injected foam.

Once the foam had hardened, it permanently bonded the cement board to the curved liner. The spill areas were cut and seamed before being connected to the liner inside the upper waterfall pool. The upper pool is also a small, planted bog area, so a 2-inch drain assembly was installed in the center to facilitate an occasional flushing and cleaning. The corner shelf with the in-pond skimmer was cut, folded and seamed.

In the corner above the upper pool, two upflow, 55-gallon-drum sand and gravel filters were installed. A small spill comes from each filter, which flows through the bog to the two spills dropping into the pond. A 57-watt LWS UV light is mounted in a downflow position inside one of the filters. A 2-inch upper drain from each filter ties into the discharge lines near the prefilters. The prefilters were covered with sealed wooden lids painted in a textured gray color to help them disappear.

The block chosen for the top cap is 14-by-24-by-2-inch Turkish travertine. Hector’s crew did an excellent job cutting and piecing the corners and curves to get a clean look. Once completed, the pool, patio and fire pit seamlessly led to the pond, making it feel as though all these elements had always existed together.