In August 2016, I was contacted by Von Winkel from the Las Vegas Springs Preserve.

The Springs Preserve is associated with the Las Vegas Valley Water District and does a lot of work to preserve the original habitat in the ancient springs that rose from the desert floor of the valley where Native Americans and eventually early pioneers settled. Early on, it was a water stop for the railroad, and the settlement grew around the pumping station and well that were established there. Listed on the National Register of Historic places since 1978 and engaged in wildlife conservation, they were charged with creating a more permanent habitat for an endangered species, the Pahrump poolfish (Empetrichthys Latos).

The Pahrump poolfish lost its natural habitat around 1975, and the rescued population has been kept in several locations around Nevada, including a hatchery. In 2015, it was time for them to build a dedicated habitat, so they entered into a safe-harbor agreement with the Department of the Interior. They wanted to create an outdoor recirculating system where the fish could thrive, protected from invasive species and predators. The space they had to work with was a long section of the original creek area surrounded by cottonwood trees. This section of the wash had been originally controlled and dammed up with some concrete and liner, but it received overflow from the upstream areas, which made it unprotected. The space was inadequate to house an endangered species.

Debbie Gifford of Green Valley Pools agreed to tackle the project, but she needed guidance, as she had never built a living feature before. I’ve been to meetings with members of the Springs Preserve numerous times over the last 10 years to advise them on issues in other parts of the wash. This would be the first time I would be involved in a project other than in a solely advisory role.

A Daunting Endeavor

Pictured in the above sequence of photos are the air manifolds, left, an air pump station.

There were a lot of challenges, especially the completion deadline of November 2016. That was over a year ago at the time of this writing, but it’s now finally coming together. Other challenges were the massive number of cottonwood leaves dropping into the water and sides that sloped down into the creek area. They wanted as close to a natural look as possible while keeping it isolated and protected in some manner. The maintenance regime had to be reasonable, and they also wanted to use the space for events, like weddings. The fish were small, at about 3 inches as adults — and we all know how hard recirculating systems and their respective equipment can be on small fish. They appear to be hardy but can’t withstand low dissolved oxygen content for long durations.

System Specifications

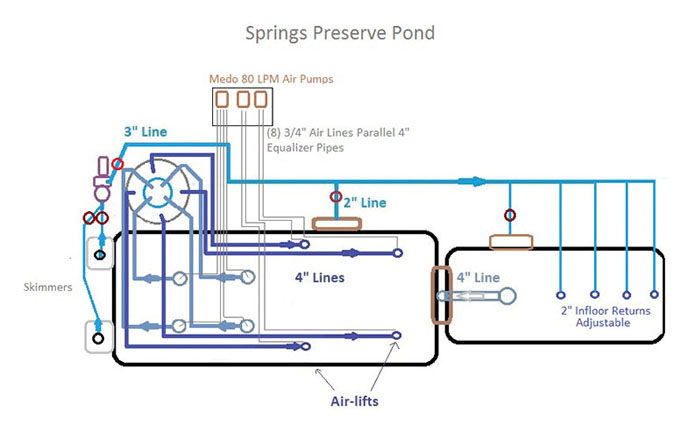

The feature was to consist of two ponds — upper and lower — and I had estimated the total volume at approximately 15,000 gallons at about 2 feet deep. We couldn’t go deeper because of the large, 4-inch overflow lines buried beneath the creek area. Above all, it had to be fish-safe, considering we needed a turnover rate of close to twice an hour to make it survivable in our desert environment.

I decided to use two of my large Helix skimmers with the 8-inch circular weirs and 24-inch baskets on the outlet end of the lower pond. The weirs on these skimmers floated very close to the surface and made it very difficult for a small fish to get over the edge, even at 4,000 to 5,000 gph. The skimmers were powered by a 10,000-gph Wlim Dragon pump, which flowed to two waterfalls, one for each pool. The 24-inch baskets would contain a large volume of leaves between cleanings. The 3-inch pipe from the pump split off into the two falls and then into four in-floor adjustable returns in the upper pond, making water flow balance much easier to achieve.

>> More best practice articles on motors, design and filtration challenges.

I wanted to build a very passively adjusted system that flowed with little or no adjustment. Water from the upper pond flowed toward the lower pond and exited through one of my trough drains, creating an active bottom drain tied into the overflow trough with no pump involved. With the drain outlet in the bottom of the trough, the 1-inch difference between the trough’s upper and lower spill edges caused the bottom drain to flow approximately 3,500 to 4,000 gph, with the balance of the flow traveling over the top edge and into the trough. I’ve used this system many times on multilevel ponds, and it always works well. It also has the advantage of holding the water level in the upper pond when the system is shut off. The level can only go down to the level of the lower spill edge before it stops.

The lower pond had four 4-inch aerated bottom drains with flush-mount 5-inch air diffusers. The bottom drains were installed on the end closest to the skimmers, creating a stream-flow design for the overall system. The drains each connected individually to a 500-gallon tank that was 4 feet in diameter, constructed as a radial separator. The water flowed upward into a center cylinder constructed from a 55-gallon drum open on both ends. The incoming water traveled upward and then reversed its flow downward, because the top of the center drum was slightly above water level. The water traveled downward at a much slower rate than it did through the 4-inch piping due to the increase in the containment diameter. When the water reached the bottom of the center drum, it reversed direction again and started flowing upward, forcing the heavier solids to fall to the bottom. The cleaner water, at an even slower rate, traveled upward toward the outlets. The water was removed from the surface of the tank through four of my 8-inch circular weirs and into the pond through four 4-inch airlifts mounted in the pond floor between the overflow trough and the drains. The circular weirs allowed the radial-separator design to be used on a pond with a fluctuating water level.

Maintenance Notes

The radial separator concept is a very efficient, yet passive way to separate heavy solids and detritus from the incoming water column. It’s also very fish-safe in that the circular weir, as mentioned earlier, is the most difficult type of weir for a small fish to enter. Some fish may end up in the tank, but they can be removed with nets and placed back in the upper pool. Any small fish that do get over the edge of the weirs will be injected safely back into the pond through the airlifts. This makes both ponds relatively fish-safe for a high-turnover system. The airlifts are safe and will keep the dissolved oxygen content consistently high. The bioconversion will be done naturally with troughs full of aquatic plants lining both sides of each pool.

If the ammonia levels can’t be kept under control with the side troughs due to fish load over time, more plants can be added to the upper pool, or a biofilter can be added to the end of the return line in the upper pool.

The airlifts are powered by two 80-lpm Medo air pumps at approximately 1 amp each, making the largest part of the turnover and oxygenation extremely efficient, at close to 20,000 gph of flow. The small, 5-inch diffusers in the drain dome centers are operated by a third 80-lpm Medo pump on a mechanical timer. Because the area is to be used as a venue, the main airlift pumps are on a reverse manual timer. This timer is normally on, so when the dial gets turned, the system shuts off for any set period (up to one hour). This allows the venue organizer to shut off the system without having to remember to turn it back on after an event (such as a wedding ceremony) is finished. I like this timer, and as it’s not listed on the Intermatic website, the part number is FF360M.

An A+ for Airlift

I’m hoping that this air-operated, fish-safe system can be used as a model for others in the future. The surrounding landscape and aesthetic finish work isn’t complete yet, but you all know what the pretty stuff looks like. Photos of the finished project will be made available later this year when the habitat is completed.

In your own community, you may find opportunities to renew or establish habitats, so keep airlift systems in mind. I was honored to contribute to this ongoing effort to support an endangered species.