Back in the mid ’80s, pond builders had far fewer off-the-shelf solutions available. We built and rebuilt what we needed to get the job done — often many times before we got it right. Here are some of my more successful Greybeard Hacks.

Bulletproof Bottom Drains

My first ponds were large, occupying the whole of a 50-by-100-foot liner or larger. They all lived in a neck of the woods on Long Island where homeowners with 2-acre lots were required to have big drywells. I put two and two together and figured I could use the big drywells to help clean out the ponds. However, I couldn’t find large enough bottom drains for the 6-inch and 8-inch pipes I was using. Even the hobbyist drains for 4-inch pipe were made for pulling koi wastes into filters, not removing large amounts of debris at high volume.

I had to build my own, and so Bulletproof Bottom Drains were born. Standard schedule 80 PVC flanges mate to either side of the liner with stainless steel bolts. We make two modifications. First, we grind any sealing ridges flat, so the whole face of the valve becomes a sealing surface. Then, we epoxy the bolt heads into one of the flanges. We install that one in the excavation with the bolts sticking up so when the liner covers them, we can cut a little “X” and work the liner down over the bolt threads.

Next, we cut the drain hole, apply silicone to both the flange under the liner and though the drain hole and the top flange, and bolt them together. Bulletproof — and scalable! I’ve built these from 2 inches to 12 inches and never had a failure in 30 years. They can even be made to work with an air diffuser, so the rising bubbles create a countercurrent that sweeps wastes into the drain.

Slab Dollys

Our simple Slab Dolly was also born of necessity. Specifically, we needed to move a triangular slab 5 feet on a side and 3 inches thick through a 36-inch gate. There were just two of us, with no machine access.

What we had were some scrap 4-by-4s and four wheelbarrows (two of which we “borrowed” for the afternoon). One trip to the hardware store for threaded stock, and the task was easy.

The hardest part was sliding the 400-pound stone off the truck and onto the dolly. Once upright, it took only one of us to move it from the driveway into the backyard in about a minute and a half. It has become a go-to for flagstone flatwork.

Rock Sled

The Rock Sled was something I had never seen before meeting my buddy Pete on a pond job. The caretaker of a Gold Coast mansion on Long Island’s North Shore, Pete appreciated the history of the mansion and grounds and used some clever gadgets from a couple of centuries ago when the horse in “horsepower” ate grass, not gas.

The Rock Sled he pulled was small but mighty — 4-by-4s bolted together to make a 2-by-4-foot sled with two iron loops in the front for chains. He drove a little Kubota tractor instead of the Old Grey Mare of song, but it made short work of moving quarter-to-half-ton stones all day long with nary a hay break.

Also known as stoneboats, you can find dozens referenced on the web like this style we used.

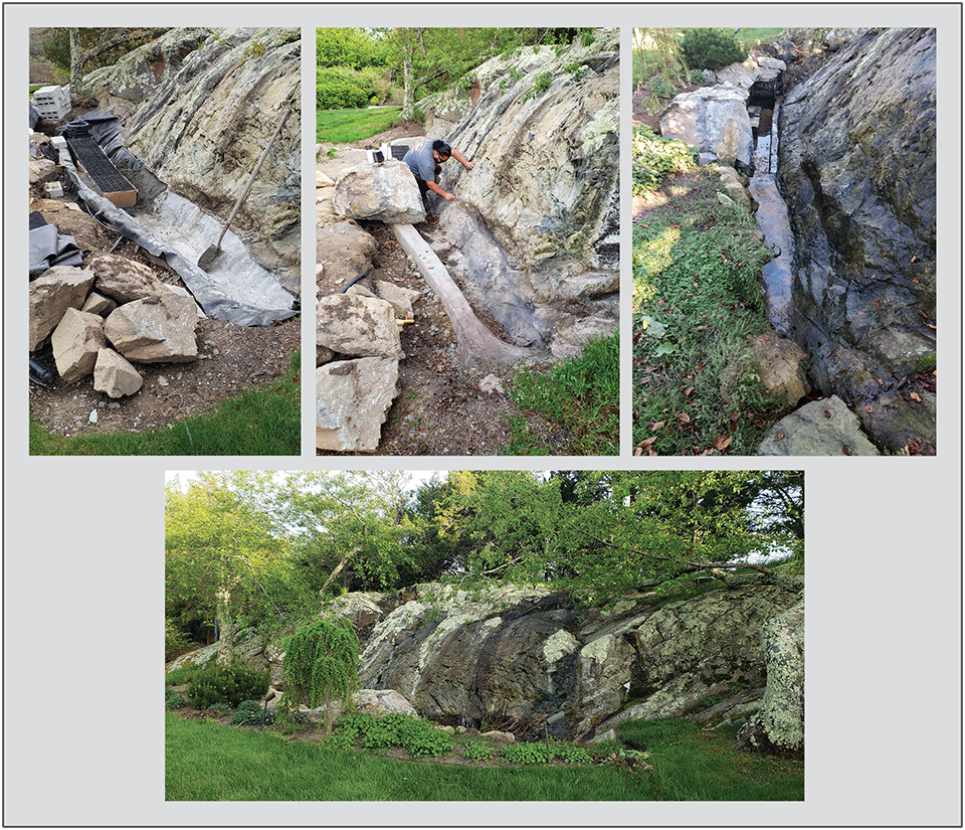

Greybeard Gunite

About 15 years ago, we had a storm that loosened a mighty oak branch above the pond in our front yard. After the tenth attempt at patching the hole it left in the EPDM liner, I gave up. It was one of my first ponds, and I had stretched the rubber into it to eliminate wrinkles.

Bad idea. Almost 20 years later, that overstretched, ancient liner just kept ripping past patch after patch when I refilled the pond. It had nothing left. So, one new liner later, I vowed that I would never worry about branches again. I borrowed a tool from the concrete dome people, the Tirolessa Sprayer, which scoops and sprays stucco mixes. I adapted the concrete so I could scoop and spray ¼ inch at a time.

It wouldn’t stick to the rubber, so I covered the EPDM with underlayment. It was anchored well at the top to keep the weight of the concrete from pulling it down. After we troweled on four additional ½-inch coats, I had a concrete armor that laughed at sledgehammers. Forget those branches!

We’ve refined it a bit for zoos and botanical gardens. Now we cover a concrete base with geotextile, then liner, then geotextile, creating a slip membrane so the liner can move freely, even if the base or top layer crack. Then we top the liner sandwich with a one-to-two mix of Portland and mason sand with an acrylic admixture and chopped fibers (“gorilla hair”) to control cracking as it wet cures. I won’t outlast these installations.

Perimeter Bog Filters

Another favorite at zoos and botanical gardens are Perimeter Bog Filters made with water matrix blocks. We’ve seen again and again that the limiting factor at such institutions isn’t funding — it’s labor. The caretakers have so much to do that the learning curve of technological solutions, such as advanced pond filters, puts them solidly out of reach, for no other reason than they need specialized maintenance that no one has time to learn.

Sediment traps, on the other hand, work completely in the background until you see muck, which can then be flushed away by opening and closing a valve. If you plant them, there’s some pruning to be done as well, but that’s old hat too. This is the opposite of modern technology; the Romans used them to remove sediments from their aqueducts.

Give moving water with suspended solids a place to slow down, and the solids will drop out. Push water into EcoBlox where the partitions will slow velocity to zero and drop out sediment. Fit a vault in the EcoBlox chamber with a bottom drain below where the water comes in, and they can be flushed clean by opening a valve. Plant up a thin layer of gravel on top of the blocks, and the plants and symbiotic bacteria will remove toxins as well. Install, then flush and prune once a year. Talk about low tech! No wonder they like them.

Demi Fortuna is Director of Product Information for Atlantic Water Gardens, traveling and working with contractors and distributors in developing targeted Atlantic sales support materials.

Demi is an awesome writer and this was a eye-opener!

Demi is a legend! I can’t wait to get him on my podcast to talk some more Gray Beard Pond Hacks!!!