There are occasions when building directly against the earth isn’t going to be your best option. In climates where the winter temperatures are severely cold, or where summer temperatures are extremely hot, an insulated pond might be your better choice. There are many ponds around the world that are built with insulation between the liner or shell and the surrounding soil to help keep the water temperature a little higher or a little lower than it would be naturally.

Some koi hobbyists in cold climates move their fish indoors for the winter and keep them in quarantine until the pond can support them again in the spring. When I was in Dubai a few years ago as a consultant, it became immediately apparent to me that the high ground and air temperatures in the summer months made koi-keeping difficult. In both of these extreme situations, an insulated pond can help stabilize the water temperature without breaking the bank. Attempting to heat an outdoor, open-air pond in a cold climate can be extremely expensive, as can cooling a pond with chillers in a warm climate.

Insulated Concrete Forms (ICFs)

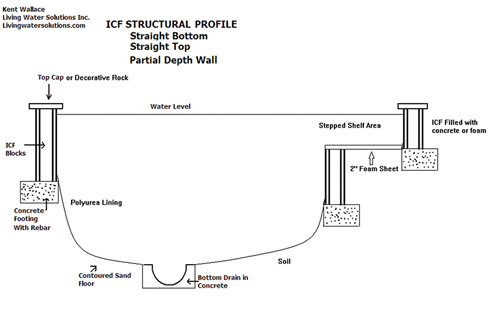

If you’re looking to construct an insulated pond wall with excellent structural integrity, my favorite choice has come to be Insulated Concrete Forms, or ICFs. Think giant Lego blocks made of foam with hollow centers. These are perfect for wall construction in buildings, coming in a variety of shapes and sizes from a multitude of manufacturers to fit every aspect of construction. Even curves and circles are available.

If I ever build another home from scratch, it will be with ICFs. After stacking and positioning the blocks, make sure to clip the rebar in place with mounts made into the blocks, and then pour concrete into the centers. This creates a double-foam, concrete wall with a very high level of insulation, or R-value.Flanged penetrations, such as skimmers, midwater drains and returns, are treated just as they would in any other pond. The floor is usually concrete, but you can use a dirt center with blocks set on a foundation ring as well. The floor doesn’t necessarily have to be insulated if it’s below the frost line. Depending on the depth of the pond, the warmer earth below the frost line can transmit the necessary heat into the water through the liner in a cold climate, while having an opposite cooling effect in a hot climate.

Construction is Simple

Once the floor or foundation ring shape has been formed and poured and rebar has been set up along the perimeter, the first course of blocks can be set. Subsequent courses can be stacked and locked together with the interlocking block forms. Wherever a penetration is necessary, a pipe and flanged connector can be installed as you stack. Insert the skimmer into the top row, just as you would for a block wall, shotcrete or gunite pond. The rebar should be clipped in place for each row as you stack.

Once the blocks are stacked and the walls are up, pour the center space with a concrete slurry, just as you would when filling block walls. However, depending on the surrounding soil type and structure, you don’t necessarily have to pour the center with concrete. You aren’t building a structure that has to support a roof or second-story floor, which is what these blocks are made for. Some options include filling the centers with pourable foam, pea gravel or sand. Pourable foam makes for a very strong structure and greatly increases the insulation factor. Any time the wall is not completely filled with concrete, it is important to lightly cover the bottom row to lock it against the floor.

After the wall is filled to within a foot of the top, pour about a foot or so below the top edge to create an upper concrete collar, increasing the structural integrity and serving as a platform for adhering the top cap in whatever form it takes. The upper blocks can also be offset, creating an upper ledge for placement of plant material, boulders or rock.

Get Creative with ICFs

Working with foam blocks is very easy and allows you to achieve virtually any shape you want. For example, some blocks are made with an angled shoulder, which can be placed as a transition from the floor to the wall. Or, a piece of foam cut on a 45-degree angle can be glued in to make the floor-to-wall transition, thus eliminating the hard corner. Once the structure is finished and ready for liner, use spray foam or urethane sealant to clean up any joints or connections that might show through the liner in an unsightly manner. A thin sheet of one-half-inch foam can be glued to an entire surface if the curves leave a blocky appearance.

Sequential photos at right of a curved ICF block for a round pond with a sheet of foam over the surface to smooth out the shapes. Photos courtesy of Tranquil Water Gardens.

My favorite liner for foam block construction, of course, is polyurea. Most types of ICFs accept polyurea very well, and when combined, they can form a formidable structure. Paul Parszik of Artisan Aquatics, Norm Walsh of Bridgeway Koi and I have built two show/quarantine tanks of ICF and polyurea that are lightweight, portable and virtually indestructible.

ICF construction doesn’t have to be limited to building for insulation. The structural integrity and ease of building can be utilized any time you find yourself building with block wall or poured concrete. After all, ICFs are the form!

Can you fibre glass the inside ? How do you finish the outside, can you you just render it ?

You can finish it with anything you like just as you would cement blocks. You could use rubber liner or fiberglass if you choose. With something like fiberglass you would want to test an area to make sure the foam won’t dissolve when the fibrrglsss is applied. If it’s a raised pond, any type of stone or tile can be applied over wire mesh or many products are made to render over foam to give you a stucco look like the outside of a home.